In 1950, Rogai Biliardi was launched in Florence under the initiative of Emilio Rogia. Right away, they began building highly prestigious artisanal Billiard tables – work which was temporarily brought to a halt in 1966 when the Arno river flooded the city of Florence on November 4 that year.

Just 10 km from the Ponte Vecchio in Sesto Fiorentino, the ideal location was found to immediately recreate Emilio's passion for Billiard tables and the craft of their construction; Emilio also had the help of his children, especially Mauro, who was taught by the best carpenters and Billiard table technicians from an early age.

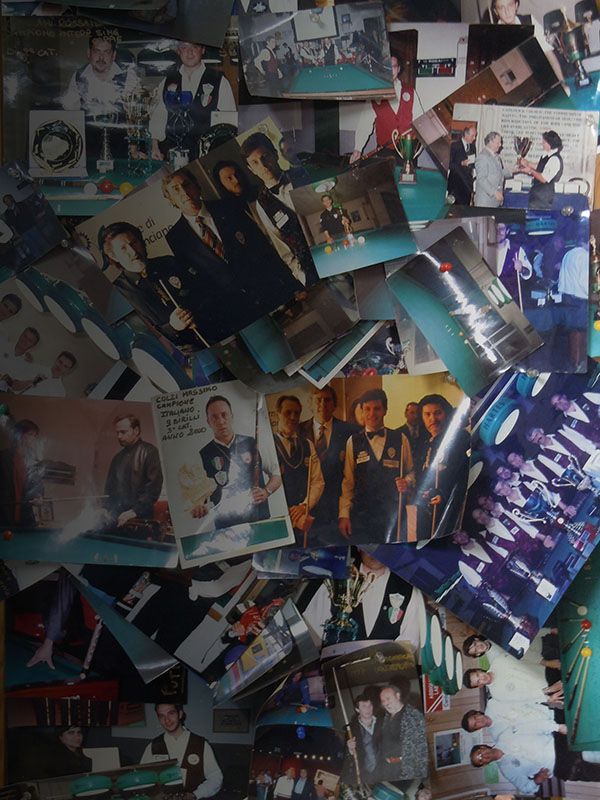

By this time, Florence was recognized by all as one of the largest Billiards schools, making use of players who had become legends of the sport. Mauro, who was a large player in this institution, was thus able to develop all his knowledge in order to expand his work to the production of Billiard cues. The professionalism of the company was further enriched with the help of Mauro's children, who performed all job roles in the company for twenty years, creating a true Billiards enterprise for three generations, and thereby developing a particularly lively and creative trade. Today, we create Billiard tables in our workshops for exclusive locations and international high-profile personalities, taking care of every detail right up to the final assembly.

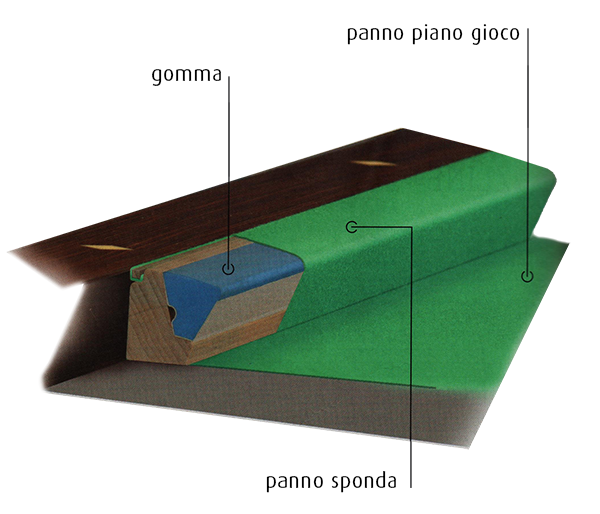

Each game discipline has a certain type of cushion rubber approved by the various international federations, but it is also possible to mount a versatile cushion rubber which caters for all types of balls and games.

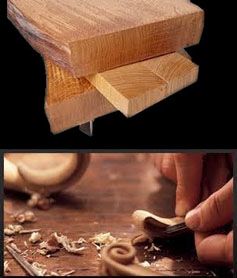

The tensional stability of the wood used to create Billiard tables is very important: Billiard tables are constructed with durability as the primary objective. Each component is tested by the experience and workmanship of our carpenters and is only incorporated into the table construction after careful verification of its suitability.

Contrary to what you might think, a dry climate is not necessary to season the wood for the first year; in fact, it is better if it is humid, like a normal cellar. This is because if there is too much of a difference between the moisture inside the wood and the ambient air, the material dries too quickly and splits. Therefore, for the first year the wood is left in a humid place with air circulation, but no ventilation, for the same reason specified above. In the years that follow, the wood is stored in places with a drier climate; in the final years it is stored warm locations, which must be absolutely avoided in the first few years. On average, it takes 10 years for a good wood seasoning.

We take the timber away from exposure to the weather, otherwise it splits completely due to changes in humidity, heat etc. causes drastic damage. The type of cut has a great impact on the seasoning. Cutting into quarters allows for better seasoning, not only in terms of drying but also for stabilization of the internal tensions which are created for various reasons when the wood is cut.

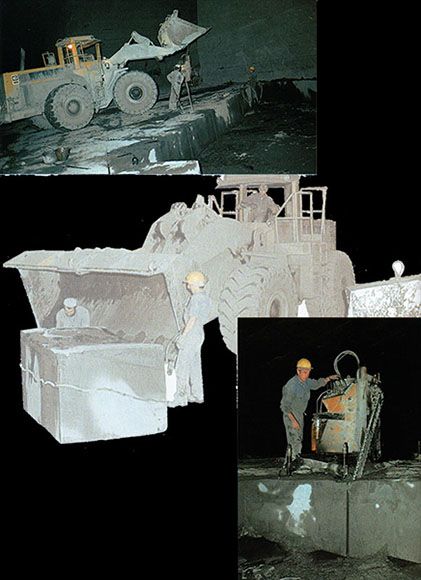

The playing surface Slate is a stone that comes from Ligurian quarries in Italy and Italian manufacturing which, with the help of modern technology, produces perfect sheets which can be used to create Billiard tables and are ready to fulfill any request for Italian and foreign tables with flat and uniform finishes.

Slate is perfectly suited for the construction of Billiard tables as it's easy to grind down and has a uniform consistency which makes it easy to process.

The surfaces are built in several thicknesses to suit the requirements of various game disciplines perfectly.

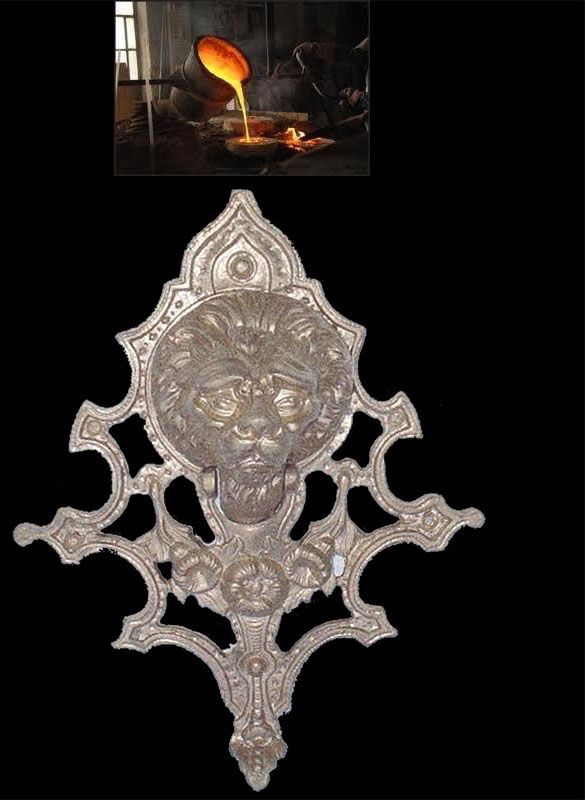

Metal casting is probably the oldest technique of metal molding and involves pouring molten metal into a cavity; once the metal has cooled, you obtain a piece that replicates the solid shape of the cavity.

The casting techniques used for pocket plates and ornate friezes are sand casting and investment casting. Depending on the shape of the objects that you want to reproduce, the first or second technique is used.

A precise and accurate model is crucial for both techniques.

Sand casting

The main element of this casting technique is to create the shape (into which the molten metal is poured) in the sand mold (special sand used in a foundry).

In order to achieve the above shape, you must have a model, i.e. a piece that is the same as or very similar to the object that you want to create.

Investment casting

We use this technique if sand casting is not suitable for reasons relating to the particular shape of the model.

The casting techniques described above allow people who need or want to create a limited number of custom-made accessories to do just that. Using a drawing or, even better, using a provided sample, the finished article can be made or the original replicated.

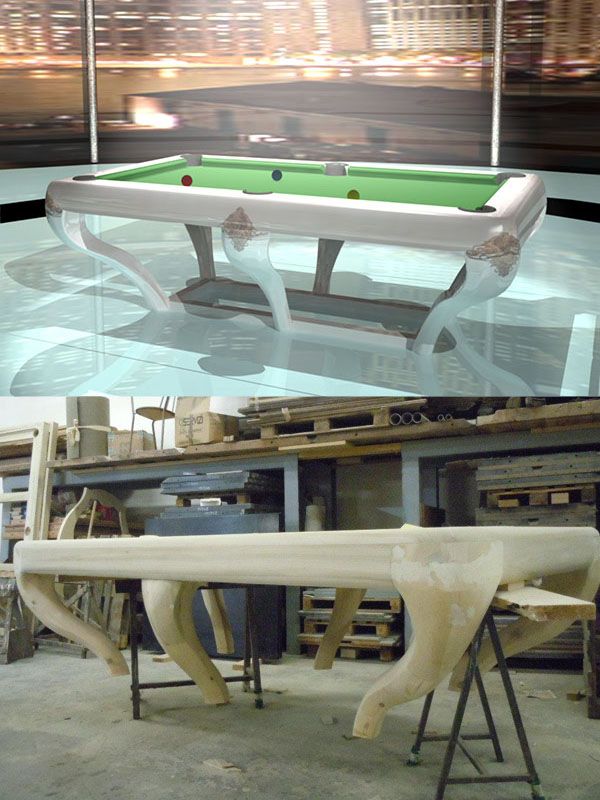

Modern tables are constructed from drawings and are designed for spaces with the most simple elegance and classic Italian craftsmanship.

The company's experience, which has been handed down for generations, makes it possible to create any kind of billiard table, based on an original design by the company or by the customer.

The finishes and details are customized for each table, as are the accessories and furnishings.

Billiard tables made to create atmospheres and moods.

Italian billiards, international Billiards, pool, snooker, French carom and Russian pyramid Billiard tables have well-defined playing surface sizes and regulatory features; each model can be produced for all game disciplines.

Conversely, if you are looking for a multi-purpose Billiard table, it will not have any compulsory technical measures, but the six mid-size or pool-sized or custom-sized holes, the intermediate rails and the playing surface size most suitable for the room, all the technical requirements of the game, will always be of the highest standard guaranteed by Rogai Biliardi.

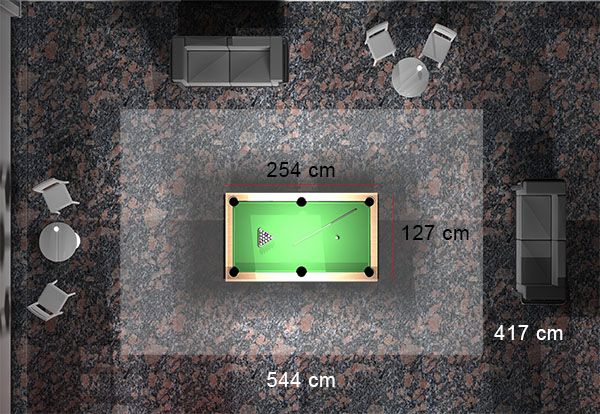

The amount space that your Billiard table will take up is proportional to the size of the playing surface, which varies depending on the type of Billiard table, and must not be confused with the external measurements (the overall dimensions); once we have ascertained the size of the playing surface, we need to add 145 cm on each side of the Billiard table (e.g. a pool table measuring 254 x 127 cm will need an area of 544 x 417 cm).

In our opinion, if we have a room which is not not overly large, we consider the fact that each item of furniture below a height of 85 cm (for example a sofa) can even be at a distance of 70/80 cm from the Billiards playing surface; we can also reduce the space required by using a shorter cue for short rail shots.

These are the standard sizes for regulatory Billiard tables and for convertible billiard tables; however, all Billiard tables can convert into regular tables.

Send your message